2K ZINC FLAKE SPRAY

ColorMatic 2K Zinc Flake Spray is a premium metal primer that provides excellent corrosion prevention. 99,9% clarity in zinc part. Applicable on all zinc, aluminium and steel substrates. Through the imbricative covering of the zinc flakes it offers insulation against humidity in an optimal way. Ideal for reparation of working damages and rust areas. Paint coating for masts, jambs, car parts, truck-type mountings. Very good adhesion. Reduces complex preparatory work, can also used as top coat. Equates to DIN EN ISO 1461. Salt spray test DIN EN ISO 9227 > 1,500 h.

Application:

Ideal for industrial applications.

QUALITY AND PROBERTIES

- Highly effective, cathodic rust protective primer

- Ideal for reparation of working damages and rust areas

- Able for spot-welding

- High covering in one working process

- Very good adhesion on zinc, aluminium, steel and also weathered hot dip

- Excellent solvent and chemical resistance

- 240°C heat resistant

- Equates to DIN EN ISO 1461

- Salt spray test DIN EN ISO 9227 >1.500 h

Do not use for car paint reparation! For underbody is possible.

PHYSICAL AND CHEMICAL DATA

- Basis of binder:Epoxy resin

- Colour:grey

- Smell:solvent

- Minimum of film layer:40 µm

- Substrate:clean, dry, fat- and rust-free

- Drying time (at 20°C, 50% relative air humidity):

Dust dry: after 40 minutes

Dry to touch: after approx. 24 h

Re-coatable: after approx. 24 h

The drying time depends on surrounding temperature, air humidity and thickness of the applied coat - Temperature resistance:to approx. 240° C

- Salt spray test DIN EN ISO 9227: > 1.500 Stunden

- Condensation water test: 240 Stunden

- Storage stability:

2 Jahre bei sachgerechter Lagerung (=10°-25°C, relative Luftfeuchte von max. 60%) - Content:

2 components aerosol cans, maximum nominal volume 200 ml - VOC-value:0,1073 kg

- Pot-life:24 hours at room temperature (20 – 25°C)

5 days at cool storage (6°C)

Befor using again warm up to room temperature (20 – 25°C).

See using instruction

ENVIRONMENT AND LABELLING

Environmentally compatible: MOTIP DUPLI is committed to apply formulations without restricted or critical ingredients and to achieve best possible performance. The caps and packagings are made of recyclable material.

Disposal: Please mind the residue inside the containers. Completely emptied containers can be used for recycling. If cans are not emptied, they should be disposed off as “special refuse”.

Labelling: All products of MOTIP DUPLI comply with the current status of their labelling regulations. Classification and distinction takes place by the presently legal form of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) or rather by CLP 1272/2008/EG regulations. Our safety data sheets comply with the current form of REACH 1907/2006/EG, article 31 und appendix II,

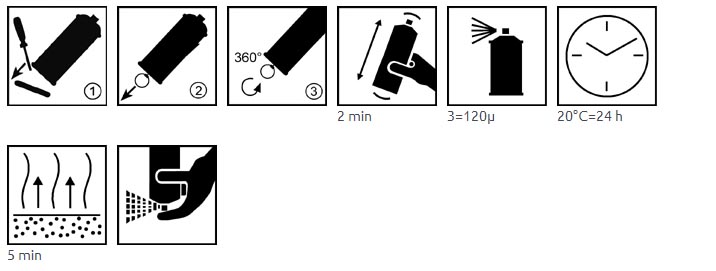

USING INSTRUCTIONS

Before use, carefully read and observe the warning texts on the label!

Vermischung der A-Komponente mit dem Härter:

- Vor dem Aktivieren der A-Komponente die Dose unbedingt so lange schütteln, bis die innenliegenden Mischerkugeln deutlich hörbar sind.

- Schutzkappe am Dosenboden entfernen und den Stift mithilfe des eingelegten Ringes bis zum Anschlag herausziehen. Dadurch wird das Messer aufgestellt und das Messer durchstößt die Wand der Aluminiumkartusche.

- Durch anschließende 360° Drehung wird die Kartusche komplett geöffnet und der Härter freigesetzt.

- Durch kräftiges Schütteln der Dose (2 Minuten) wird nun die A-Komponente mit dem Härter im richtigen, vorgegebenen Mischungsverhältnis vermischt.

- Probesprühen

- Topfzeit: 48 Std. (20°C)

- Nur zur Benutzung durch den Fachmann

- Geeignete Atemschutzmaske tragen (wir empfehlen Typ A2/P3)

ANWENDUNG

Mixing A components with hardener:

- Remove the protection cap from the bottom of the can and pull the pin out fully with the help of the inserted ring. This will release the knife, which will penetrate the wall of the aluminium cartridge.

- The cartridge will then rotate 360 °, be completely open and release the hardener.

- Shake the can vigorously to mix the A components with the hardener in the proper, predetermined ratio.

- Shake can vigorously for 2 minutes

- Carry out spray tests

- Pot life: 24 hours (20 ° C)

- For professional use only

- Wear an appropriate respirator (recommended type A2/P3)

TIPPS ZUR ANWENDUNG

Vor Gebrauch die Dose auf Raumtemperatur (20 – 25°C) bringen. Dazu die Dose in handwarmes Wasser legen.

HINTS CONCERNING APPLICATION

Bring can to room temperature prior to use (20 – 25 °C). Place the can in lukewarm water for this purpose.

ORDER INFORMATION

| Color | Product | Bundle | Art.No. |

| CM 2K Zinkflake m. Härter 200 | 200 ml | 325816 |

The presentation of colors may deviate from the original color.

EXAMPLES OF USE

DISCLAIMER OF LIABILITY

This application-technological information is given to the best of our knowledge. The notes mentioned herein are, however, non-binding and do not exempt you from own tests to see whether the products supplied by us are suitable for your special application. The use and processing is beyond our control and therefore exclusively in the responsibility of the user. MOTIP DUPLI is let off the liability, unless the liability-based incident is caused by a fault incurred to MOTIP DUPLI.

For any further technical questions call our hotline +49 (0) 62 66 75-266 from Monday to Thursday from 9 h a.m. to 3 h p.m. or on Friday until 12 h p.m.

As of February 2, 2012

This release replaces all eventually earlier issued versions

PORUDŽBENI BROJEVI

| Color | Product | Bundle | Art.No. |

| CM 2K Zinkflake m. Härter 200 | 200 ml | 325816 |

The presentation of colors may deviate from the original color.